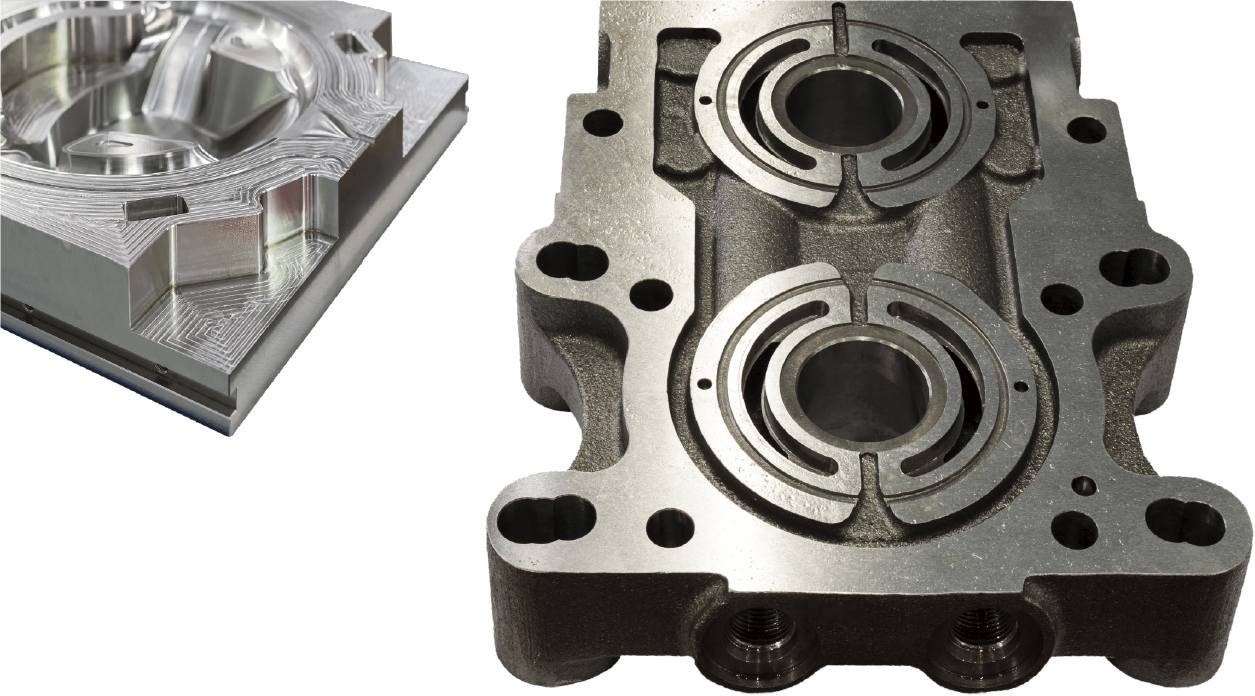

CNC Machined Metal

Parts in days anywhere in the USA.

Prototek offers exceptional quality machined metal that meets your project’s specific requirements. Our skilled machinists have vast experience working with various metals, ensuring precision and superior results. We prioritize customer satisfaction and provide an unmatched excellent experience—Trust Prototek for your machining needs.

Choosing the right machined metal for your project.

Choosing a suitable machined metal is crucial for the success of any project. The selection process involves considering the desired mechanical properties, corrosion resistance, and cost-effectiveness. First, identify the application requirements, such as strength, ductility, and hardness. For example, stainless steel, aluminum, and brass are commonly used for their high strength, lightweight, and corrosion-resistant properties. Consider the environmental conditions where the project will be applied, such as temperature and humidity, to prevent degradation. Finally, examine the cost-effectiveness of the available materials based on your budget, availability, and required quantity. Collaborate with a reputable machining shop, such as Prototek, to determine the best-machined metal choice that meets your project’s quality, efficacy, and cost-effectiveness needs.

Aluminum

Price | $

Aluminum is a strong and lightweight material that is used in various industries, including aerospace, automotive, and medical. It is well-known for its ability to manufacture precise parts that meet specific requirements. Due to its durability and longevity, aluminum is widely used in critical components across various industries.

Brass

Price | $$

Brass is a popular material used in manufacturing and machining processes because of its durability and excellent mechanical properties. Its features include corrosion resistance, high tensile strength, and good conductivity. Brass is used in various applications, including creating high-precision parts and components for the aerospace and automotive industries. It also produces decorative and ornamental objects such as figurines and sculptures.

Bronze

Price | $$

Bronze is a highly durable metal resistant to corrosion, making it an excellent choice for various aerospace, automotive, marine, and medical industries. It is commonly used for making valve components, bearing housings, bushings, and gears. Bronze is a versatile material that is easy to work with and is available in various shapes and sizes.

Copper

Price | $$

Copper is a versatile metal widely used in various industrial applications due to its exceptional thermal and electrical conductivity, corrosion resistance, and antimicrobial properties. The electronics, automotive, aerospace, and medical industries rely on copper for its unique properties and durability. Copper can be polished, coated, and plated to enhance appearance and functionality. These finishing techniques are commonly employed to improve the quality of copper products.

Nickel Based High-Temp Alloys

Inconel

Price | $$$

Inconel is a superalloy primarily made of nickel, chromium, and iron. Due to its unique properties, it is widely used in industries such as aerospace, medical equipment, and chemical processing. The material comes in various grades tailored to specific applications and environments, but machining it can be challenging. Inconel is used in high-end applications like aircraft engines, gas turbine components, nuclear reactors, medical implants, and surgical instruments due to its biocompatibility and resistance to corrosion.

Invar

Price | $$$

Invar is a unique type of superalloy with a very low thermal expansion coefficient. This means it does not significantly expand or contract when exposed to changes in temperature, making it ideal for use in precision instruments and scientific applications where dimensional stability is critical. Invar is composed of a precise combination of nickel, chromium, and iron, with low levels of impurities. Its unique properties make it popular in electrical and electronic devices, scientific instruments, and aerospace engineering applications.

Kovar

Price | $$$

Kovar is an iron-nickel-cobalt alloy with unique properties, including a low coefficient of thermal expansion (CTE), high thermal conductivity, and excellent oxidation resistance. These characteristics make Kovar well-suited for electronic and optical applications, such as airtight seals, vacuum tubes, and X-ray tubes. Additionally, Kovar is easy to machine and has good weldability (if not plated), making it versatile and practical in various industries.

Nitronic 60

Price | $$$

Nitronic 60 is a high-performance austenitic stainless steel known for its exceptional strength, corrosion resistance, and wear resistance, even at high temperatures. Composed of a unique combination of elements, including chromium, nickel, silicon, manganese, nitrogen, and iron, this material is well-suited for demanding industrial applications such as aerospace, chemical processing, and marine engineering. Nitronic 60 offers superior mechanical properties to standard austenitic stainless steels, making it an excellent choice for components requiring high strength, toughness, and durability in harsh environments.

Stainless Steel

Price | $$$

Stainless steel is a type of steel that undergoes a machining process. It is widely used in manufacturing due to its high strength, corrosion resistance, and attractive appearance. However, machining stainless steel can be challenging because of its hardness and rigid properties. The aerospace, automotive, and medical industries use different grades of stainless steel, such as 304, 316, and 420. Stainless steel components are machined in various sizes and complexities for applications like surgical instruments, automotive parts, and industrial machinery.

Steel

Price | $

Steel is a versatile and durable material widely used in various industries. At Prototek Digital Manufacturing, we use our expertise in CNC machining to produce high-quality steel components that meet the most demanding specifications. Precise tolerances, exceptional finishes, and consistent performance make machined steel a reliable choice for various applications.

Titanium

Price | $$$$

Titanium is a solid, lightweight metal that can be shaped and cut using precision machines to create components with unique properties. These components have exceptional strength, making them ideal for applications where durability is critical. Additionally, titanium has a low density, allowing lightweight machined components without sacrificing strength. It is highly resistant to corrosion and can withstand harsh environments, such as those with high moisture levels, salt, or acid. Surface treatments such as anodizing or passivation can further enhance these properties in titanium components.

Tool Steel

Price | $$$$

Tool steel is a durable and robust alloy used in precision operations and cutting machinery in industries such as automotive and aerospace. Its composition includes tungsten, chromium, and vanadium, which enhance its wear resistance, corrosion resistance, and strength. Engineers use heat treatment processes to increase its hardness and toughness, improving its resilience. Machined Tool Steel manufactures high-quality tools and components from this material.

Cost: $ (cheap)- $$$$ (expensive)

If there is a type of metal material you’re interested in that isn’t listed here, please let us know! We can try to source it for you. Please note that quotes for new materials may take a little longer to provide.

CNC Milling

OEM

Akira Seiki, Atrump, Bridgeport, Brother, Daewooo, DMG Mori, Doosan, Haas, Hurco, Kent USA, Lagun, Matsuura, Mazak, OKK, Sharp, Sodick

Lead Time

5 – 22 Days

Max Dimensions

84 x 34 x 30 in

Prototek has many machines with different dimensions. This is the largest dimension available.

CNC Turning

OEM

Acra-Turn, Atrump, Daewooo, Doosan, Enco, Haas, Hardinge, Hurco, Mazak, Trak Lathe

Lead Time

5 – 22 Days

Max Dimensions

XYZ | 84 x 34 x 30 in

Diameter | 12 in

Swing | 26 in

CNC Turning

OEM

Fanuc & Sodick

Lead Time

5 – 22 Days

Max Dimensions

31.5 x 23.6 x 31.5 in thick